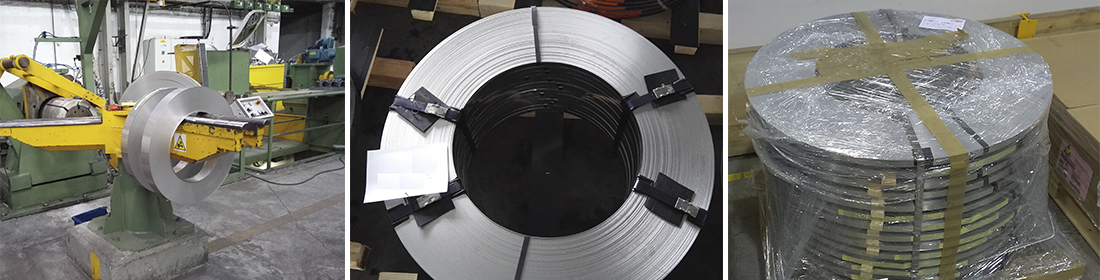

A given service is considered as the following operations:

- Reducing the width of the coils / converting a wide coil into several narrower ones

- Cut off the edge of the coil

- Cutting the coil into strips

Coil slitting technical data (strips cutting)

| Thickness range | od 0,10 mm do 3,00 mm |

| Maximum width | 1500 mm |

| Minimum tape width | 10 mm |

| Inside diameter of the coil | 508 / 610 mm |

| Maximum outer diameter of the coil | 1840 mm |

| Maximal weight of the coil | do 12,0 t |

| The precision of the operation | – ordinary – increased (precise) – special (according to customer specification) |

| The degree of amplification | – soft – semi-hard – hard – spring |

Slitting stainless steel coils into strips is a process in which coils of stainless steel are slit along the length to form strips of specified widths. This process is important in the metallurgical industry and is used in many different applications, including the production of pipes, cables, electronic components.

The process of slitting coils into strips is usually carried out using special machines, called strip slitting mills. These machines usually consist of three basic components: a driving roller, a cutting roller and a guide roller. The stainless steel coils are passed through the machine and a slitting roller cuts them along the length to form strips of a predetermined width.

An important factor in the quality of slitting stainless steel coils into strips is the selection of the appropriate cutting speed. Cutting speed that is too slow can cause the steel to twist and distort, leading to uneven strip widths and imperfect cuts. Too high a cutting speed, on the other hand, can cause excessive resistance and overheating of the machine, which can damage the cutting tools.

Therefore, in order to achieve the best results when slitting stainless steel coils into strips, careful calculations and tests are necessary to select the optimum parameters for the cutting process.